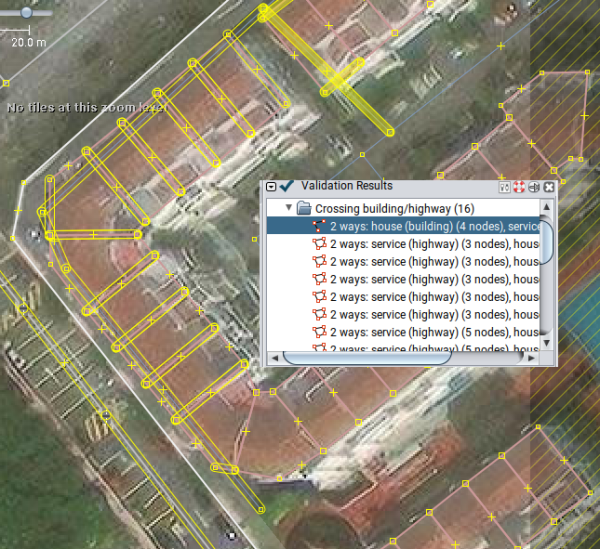

Straße/ Weg falsch eingezeichnet. Führt zu unschönen Problemen

Straße/ Weg falsch eingezeichnet. Führt zu unschönen Problemen

https://www.openstreetmap.org/#map=17/54.618512/9.361435OpenStreetMap

Part 1: https://www.openstreetmap.org/user/Negreheb/diary/405306

Part 2: https://www.openstreetmap.org/user/Negreheb/diary/406030

Part 2: https://www.openstreetmap.org/user/Negreheb/diary/406030

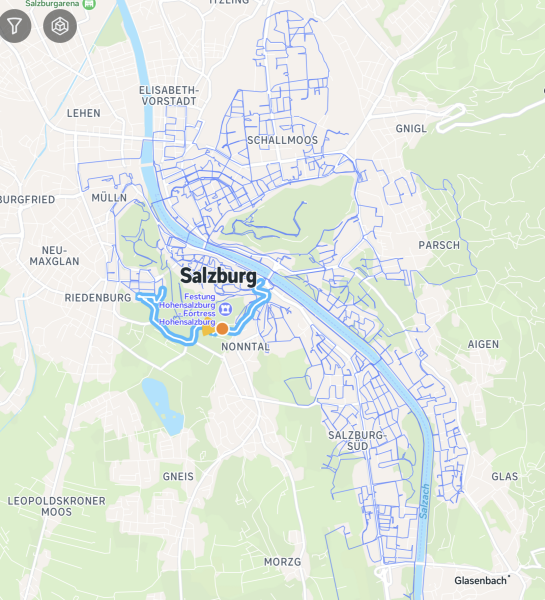

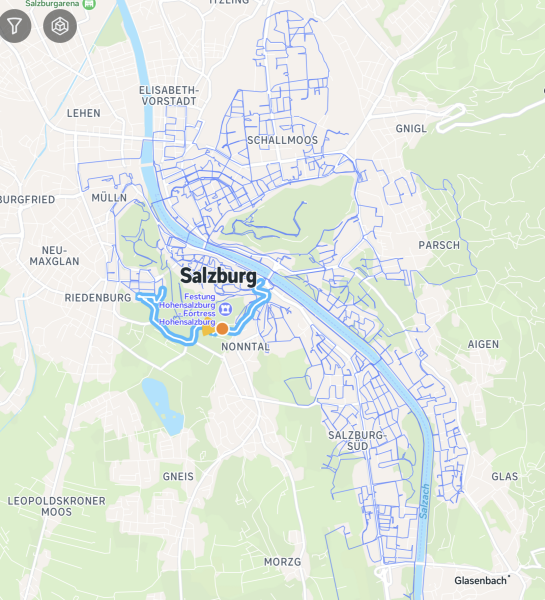

Capturing the whole city of Salzburg in 360°: Better Mounting, Better Coverage (Part 3)

Part 1: https://www.openstreetmap.org/user/Negreheb/diary/405306 Part 2: https://www.openstreetmap.org/user/Negreheb/diary/406030OpenStreetMap

Dear OSM Community and Team, Is there any possibility of accessing a newer imagery layer, such as Maxar? The current Bing Maps Aerial imagery appears to be significantly outdated, which makes it challenging to accurately update or edit map content.

I see many diaries on OSM, but unfortunately the good ones are hard to find, if they can be found at all.

This is my my second day into the field of OSM, i went back and edited my home grown plce, yuh my home village and and waiting to welcome any reviews because i believe it is the right think to do and am welcoming any mistakes and am hoping to add many more places on the OSM today I went ahead and edited my villages by adding the various buildings and trees that haven’t been mapped yet

Editing

This is my my second day into the field of OSM, i went back and edited my home grown plce, yuh my home village and and waiting to welcome any reviews because i believe it is the right think to do and am welcoming any mistakes and am hoping to add man…OpenStreetMap

so i’m nearing my 10,000th edit on openstreetmap.

wild. i’ve been thinking a lot about what that actually means.

what started as a hobby - or maybe an obsession - has slowly become a record of care.

a way to see.

a way to let others see.

mapping Bangkok, piece by piece.

making it just a little more visible.

a little more precise.

a little more known - to others,

and to myself.

i’ve been thinking a lot about maps.

about what this whole thing has meant - not just as a mapper,

but as a local voice,

a small thread in a bigger web, by others.

by myself.

by the place itself.

piece by piece.

making it just a little more visible.

a little more precise.

a little more known - to others,

and to myself.

-

i’ve always loved maps.

even when i didn’t know the word for what i was feeling.

as a kid, i was drawn to them like magnets.

atlases in bookshops. globes with soft pastel oceans.

the tiny maps printed on the backs of business cards.

spatial things made me feel calm.

made me feel like the world could be held in my hands.

Vast space compress into something compact, 2 dimensional.

-

my first game was simcity 4 - my dad played it.

i didn’t really get it,

but i still did play it.

a lot,

to much, maybe.

then came minecraft.

and yeah, like every gen z kid,

i was obsessed. not the survival part.

i built cities.

creative model.

little parks and structures.

entire worlds.

i think i was looking for something i hadn’t seen yet in real life.

or maybe building the kind of place i wanted to see.

-

i still don’t know where the fascination comes from.

maybe it’s an autistic special interest.

maybe it’s just how i’ve always tried to make sense of things - through shapes,

through patterns,

through place.

-

it was the monsoon season of 2021.

midst of covid lockdown. my last year of high school. rain on the roof every day.

i opened openstreetmap one night and… that was it.

the editor was slow, clunky, frustrating - but something about it felt right.

i mapped a street.

then my school.

then a neighborhood.

then a whole district.

and then i edit.

and edit.

like nothing else matters.

i know it’s not healthy.

i know i’m not supposed to feel this alive hunched over a screen, tracing lines, renaming bus stops, aligning satellite tiles until my eyes blur.

but it satisfies something.

something deep.

something hidden in a place i don’t have a name for.

a warm ache in the center of me that only quiet edits can soothe.

so i keep going.

i expand.

translating tools like josm into thai, writing wiki articles, answering forum posts like i’ve been part of this community forever.

and maybe i have.

maybe this is my hometown, too.

not the real one, but the mapped one.

the shared one.

the infinite, editable one.

and now i’m here.

thousands of edits later.

still tracing, still tagging.

still trying to name things.

still looking for a way to understand the world a little better.

openstreetmap is familiar to me now.

like an old friend.

like a ritual.

and somewhere along the way i realized -

i believe in open-source.

i believe in open-content.

i believe geographical data is a human right.

i believe it should be free.

for everyone.

forever.

and yes -

i do love openstreetmap

-

thanks for reading. if you’re here, you probably get it.

-

🗺️✳️

krittin

wild. i’ve been thinking a lot about what that actually means.

what started as a hobby - or maybe an obsession - has slowly become a record of care.

a way to see.

a way to let others see.

mapping Bangkok, piece by piece.

making it just a little more visible.

a little more precise.

a little more known - to others,

and to myself.

i’ve been thinking a lot about maps.

about what this whole thing has meant - not just as a mapper,

but as a local voice,

a small thread in a bigger web, by others.

by myself.

by the place itself.

piece by piece.

making it just a little more visible.

a little more precise.

a little more known - to others,

and to myself.

-

i’ve always loved maps.

even when i didn’t know the word for what i was feeling.

as a kid, i was drawn to them like magnets.

atlases in bookshops. globes with soft pastel oceans.

the tiny maps printed on the backs of business cards.

spatial things made me feel calm.

made me feel like the world could be held in my hands.

Vast space compress into something compact, 2 dimensional.

-

my first game was simcity 4 - my dad played it.

i didn’t really get it,

but i still did play it.

a lot,

to much, maybe.

then came minecraft.

and yeah, like every gen z kid,

i was obsessed. not the survival part.

i built cities.

creative model.

little parks and structures.

entire worlds.

i think i was looking for something i hadn’t seen yet in real life.

or maybe building the kind of place i wanted to see.

-

i still don’t know where the fascination comes from.

maybe it’s an autistic special interest.

maybe it’s just how i’ve always tried to make sense of things - through shapes,

through patterns,

through place.

-

it was the monsoon season of 2021.

midst of covid lockdown. my last year of high school. rain on the roof every day.

i opened openstreetmap one night and… that was it.

the editor was slow, clunky, frustrating - but something about it felt right.

i mapped a street.

then my school.

then a neighborhood.

then a whole district.

and then i edit.

and edit.

like nothing else matters.

i know it’s not healthy.

i know i’m not supposed to feel this alive hunched over a screen, tracing lines, renaming bus stops, aligning satellite tiles until my eyes blur.

but it satisfies something.

something deep.

something hidden in a place i don’t have a name for.

a warm ache in the center of me that only quiet edits can soothe.

so i keep going.

i expand.

translating tools like josm into thai, writing wiki articles, answering forum posts like i’ve been part of this community forever.

and maybe i have.

maybe this is my hometown, too.

not the real one, but the mapped one.

the shared one.

the infinite, editable one.

and now i’m here.

thousands of edits later.

still tracing, still tagging.

still trying to name things.

still looking for a way to understand the world a little better.

openstreetmap is familiar to me now.

like an old friend.

like a ritual.

and somewhere along the way i realized -

i believe in open-source.

i believe in open-content.

i believe geographical data is a human right.

i believe it should be free.

for everyone.

forever.

and yes -

i do love openstreetmap

-

thanks for reading. if you’re here, you probably get it.

-

🗺️✳️

krittin

9999 edits - a love letter to OpenSteetMap

so im nearing my 10,000th edit on openstreetmap. wild. ive been thinking a lot about what that actually means. what started as a hobby - or maybe an obsession - has slowly become a record of care. a way to see. a way to let others see.OpenStreetMap

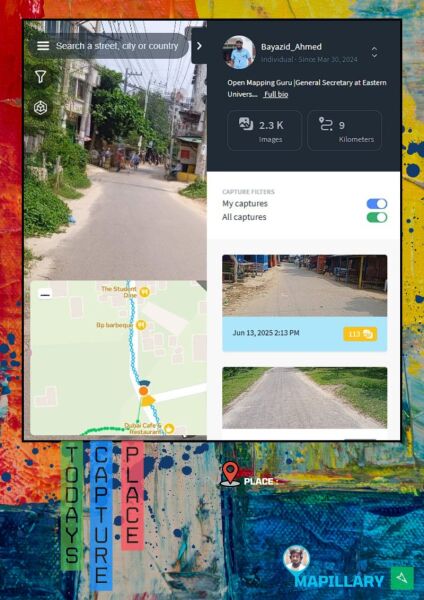

This project began with my own steps — capturing street-level imagery from Daffodil International University to Eastern University, Dhaka, Savar. Using Mapillary, I documented the road to support open mapping.

are eligible for free unlimited map downloads and live updates. To qualify: Enable the OpenStreetMap Editing plugin. Log in with your OSM username. Maintain at least 30 edits over the last two months.

Hello everyone,

I would like to request the addition of a missing village to OpenStreetMap. The village is called Charchall, located in the Akre District, Sawsana Subdistrict, Duhok Governorate, in the Kurdistan Region of Iraq.

Basic information:

🏘️ Village name: Charchall

🗺️ District: Akre

🏞️ Subdistrict: Sawsana

🏴 Governorate: Duhok – Kurdistan Region, Iraq

🧾 Postal Code: 24005

🛣️ Main connecting road: Charchall Road

📍 Nearby village: benatah

This village is recognized by local government maps, but it is still missing from OpenStreetMap. We kindly ask for it to be added so that the area can be better represented for residents, navigation, and future development.

I would like to request the addition of a missing village to OpenStreetMap. The village is called Charchall, located in the Akre District, Sawsana Subdistrict, Duhok Governorate, in the Kurdistan Region of Iraq.

Basic information:

🏘️ Village name: Charchall

🗺️ District: Akre

🏞️ Subdistrict: Sawsana

🏴 Governorate: Duhok – Kurdistan Region, Iraq

🧾 Postal Code: 24005

🛣️ Main connecting road: Charchall Road

📍 Nearby village: benatah

This village is recognized by local government maps, but it is still missing from OpenStreetMap. We kindly ask for it to be added so that the area can be better represented for residents, navigation, and future development.

Today is my introduction to OSM through an internship process by Mr Samson who take as through an online intern, we are getting into it before you know it and this will mark the start of one of the greatest open street mappers who has ver been born, am actually learning a lot from this process and looking forward to contributing so much to the members of the community, we wanna make Uganda great and make my village the best in the world

Introduction

Today is my introduction to OSM through an internship process by Mr Samson who take as through an online intern, we are getting into it before you know it and this will mark the start of one of the greatest open street mappers who has ver been born, …OpenStreetMap

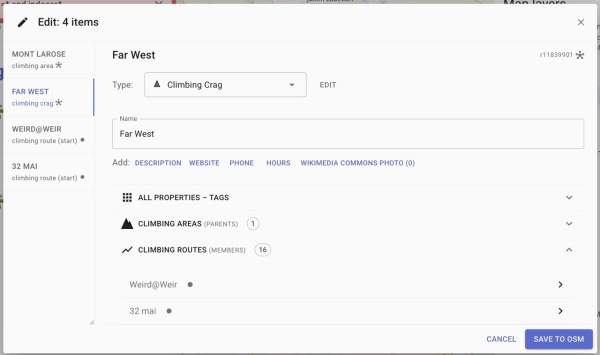

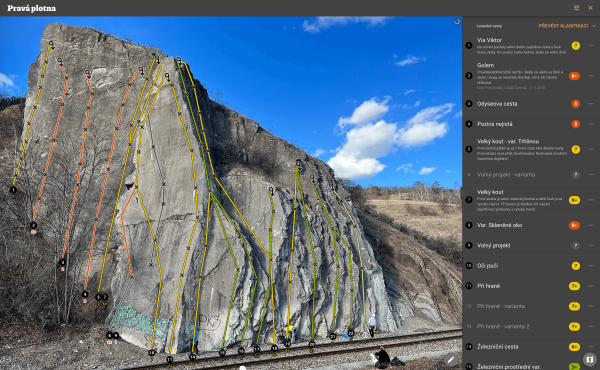

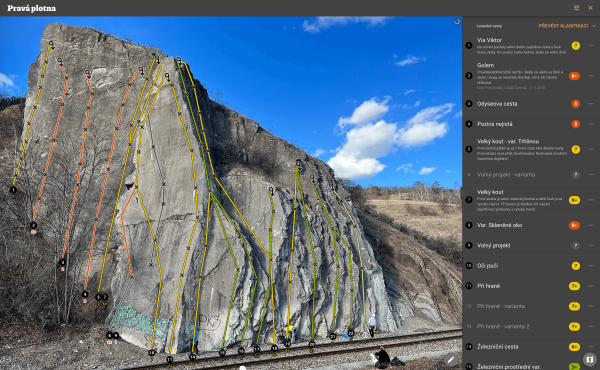

The goal of https://openclimbing.org is to offer a non-commercial alternative to traditional climbing apps. Instead of filling private databases, we decided to design a structure for mapping climbing routes directly into OpenStreetMap.

Openclimbing.org - climbing guides & topos in OpenStreetMap

The goal of https://openclimbing.org is to offer a non-commercial alternative to traditional climbing apps. Instead of filling private databases, we decided to design a structure for mapping climbing routes directly into OpenStreetMap.OpenStreetMap

UM980 is relatively affordable chip allowing multi-constellation multi-frequency GNSS with capability to provide raw phase measurements and hence potentially suitable for use in OpenStreetMap environment for precise mapping susing RTK.

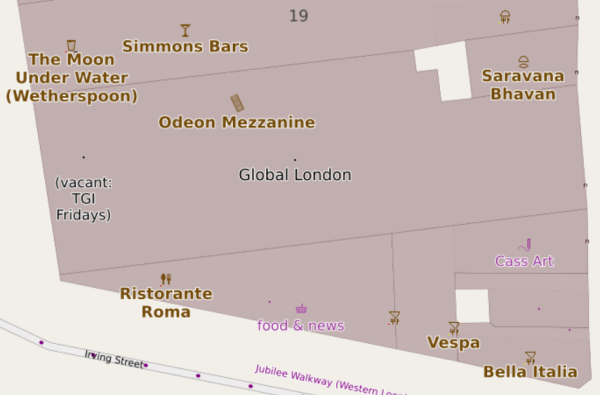

What food is there - and can I get a wheelchair in?

I had a fantastic time at SOTM US. Thanks to all at OSM US for their work putting the event together.

Just reached 1000 edits, so thought it would be good to dump what I have learnt so far.

I started using OSM during the COVID 19 lockdown living in Hampshire, there were many walks available but the routes were not always clear on google maps. OSM was far better and I used it for information about walks before proceding. The level of detail was great and really useful.

Fast forward to 2023 and I decide to start contributing using StreetComplete and MapComplete. I drive an Electric vehicle and the information on charge points is so obscure I wanted to contribute. This led me down a rabbit hole of StreetComplete, filling in addresses, road surfaces, bus stop shelter. Anything and everything. I learnt the importance of information that would be useful to users.

Only in the last year, have I picked up mapping, this time using ID editor, chnaging tags was a little daunting but I slowly got there. I noticed some areas around me were missing house numbers. I learnt the importance of doing a survey on foot. There’s so much to learn from looking around IRL.

The last few weeks, I have been mapping out areas that had no buildings, only Residential Areas. A few thousand terraced houses later (feels like it) and quite a few places are on the map around Yarmouth (yeah I moved from Hampshire in this time!). Most imporatntly, check the alignment of background layers before starting a new edit! It is also useful to turn off layers not used, really makes things easier to see.

Latest update, I own a drone and can produce aerial images, very useful for areas not on Bing maps. This also gives me access to a 3D view of the area, very useful for double checking my survey notes!

Maybe I’ll do another one of these at 2000 edits?

I started using OSM during the COVID 19 lockdown living in Hampshire, there were many walks available but the routes were not always clear on google maps. OSM was far better and I used it for information about walks before proceding. The level of detail was great and really useful.

Fast forward to 2023 and I decide to start contributing using StreetComplete and MapComplete. I drive an Electric vehicle and the information on charge points is so obscure I wanted to contribute. This led me down a rabbit hole of StreetComplete, filling in addresses, road surfaces, bus stop shelter. Anything and everything. I learnt the importance of information that would be useful to users.

Only in the last year, have I picked up mapping, this time using ID editor, chnaging tags was a little daunting but I slowly got there. I noticed some areas around me were missing house numbers. I learnt the importance of doing a survey on foot. There’s so much to learn from looking around IRL.

The last few weeks, I have been mapping out areas that had no buildings, only Residential Areas. A few thousand terraced houses later (feels like it) and quite a few places are on the map around Yarmouth (yeah I moved from Hampshire in this time!). Most imporatntly, check the alignment of background layers before starting a new edit! It is also useful to turn off layers not used, really makes things easier to see.

Latest update, I own a drone and can produce aerial images, very useful for areas not on Bing maps. This also gives me access to a 3D view of the area, very useful for double checking my survey notes!

Maybe I’ll do another one of these at 2000 edits?

Didn’t think would see a day(again) where I have to use tor with bridge as proxy AND a vpn for accessing internet including OSM and it’s wiki but here we are… Sighs🤦🤦🤦

Those guys at government always can and will shock/surprise civilians to the death (yet again)

Never a dull moment!

Those guys at government always can and will shock/surprise civilians to the death (yet again)

Never a dull moment!

ah shit, here we go again

Didnt think would see a day(again) where I have to use tor with bridge as proxy AND a vpn for accessing internet including OSM and its wiki but here we are Sighs 🤦🤦🤦OpenStreetMap

Enthusiastic ▪︎ Speculator ▪︎ Adaptable Loves to travel, close to nature, humble towards animals, stubborn towards life.

Hi everyone. I recently started contributing to the map around my university’s campus, and I thought I should get in touch with the community a little. I’ve only labeled major buildings in the campus plus some road fixups, but I hope to continue contributing more to the map around here.

Oh yeah, this account is old, but I don’t even remember having it until I tried to sign up lol.

Oh yeah, this account is old, but I don’t even remember having it until I tried to sign up lol.

Hello, OSM!

Hi everyone. I recently started contributing to the map around my universitys campus, and I thought I should get in touch with the community a little.OpenStreetMap

I typically write my notes in English when they can be resolved by anyone. Even residents from another country than Sweden.

Om anteckningarna pekar mot att en behöver kunna förstå svenska för att fixa ett problem så tenderar skriva jag på svenska istället.

Om anteckningarna pekar mot att en behöver kunna förstå svenska för att fixa ett problem så tenderar skriva jag på svenska istället.

Language/språk

I typically write my notes in English when they can be resolved by anyone. Even residents from another country than Sweden.OpenStreetMap

Spending countless hours terracing thousands of buildings yet didnt even bother to correct the errors caused by it?

Discussion Post for MapSwipe Today and it’s future in OSM talk at SoTM US 2025

This week I’ve been mapping rural communities in Honduras, focusing on areas within the Tegucigalpa Health Region. My work has included adding paths, correcting road alignments, and identifying visible structures such as houses and community centers.

Today we at Unique Mappers did our weekly presentation were I made a presentation on Humanitarian Use of OpenStreetMap where i talked about OSM what it is why it is crucial in Humanitarian context how it provides critical data in poorly mapped or un mapped areas. I still talked about the basics( getting started with OSM), the intermediate OSM data use(Analysis and virtualization) and advanced used of OSM. I still talked about the tools and resources( software) used with OSM and example is the HOT tasking manager, QGIS [qgis.org], Umap and many other software, site, organisation using OpenStreetMap

Weekly Presentation

Today we at Unique Mappers did our weekly presentation were I made a presentation on Humanitarian Use of OpenStreetMap where i talked about OSM what it is why it is crucial in Humanitarian context how it provides critical data in poorly mapped or un …OpenStreetMap

Hi :)

I am mapping Eritrea these days and found some objects I am not able to identify. Can you help me with your wisdom?

I am mapping Eritrea these days and found some objects I am not able to identify. Can you help me with your wisdom?

As I write in my profile, I was really peeved off, that dozens of Camino Apps (apps used to track users along the Ways of St.

This blog was originally posted on my personal site:

Just a quick blog post on some coastline work I was doing.

For the OSMF Shortbread vector tiles I had to identify when coastlines has changed. The solution I came up isn’t specific to Shortbread, but is useful for anyone using the tiled ocean shapefiles.

I’m going to start by assuming that the old ocean data is in

To start I want to find any geometries that have changed. For geometries in the new data that aren’t in the old data, I can get this with a

A

SELECT ST_SymDifference(ST_Collect(old.way), ST_Collect(new.way)) AS dgeom

FROM water_polygons AS old

FULL OUTER JOIN loading.water_polygons AS new

ON old.way = new.way and old.x = new.x and old.y = new.y

WHERE new.way IS NULL OR old.way IS NULL

GROUP BY COALESCE(old.x, new.x), COALESCE(old.y, new.y)

This gets me the difference in geometries for the entire world in about two minutes. But I need tiles, which is it’s own complication.

I need to intersect the changes with potential tial geometries. This could be done by generating lots of tiles with ST_TileEnvelope, but there’s a better function. ST_SquareGrid generates the square grid that covers a geometry’s bounding box. If I use the right settings, these correspond to standard tiles. I can then exclude any that don’t intersect the geometry.

This can be done with

SELECT

...

FROM differences,

generate_series(10,14) AS z,

ST_SquareGrid(40075016.685578/2^z, differences.geom) AS squares

WHERE ST_Intersects(differences.geom, squares.geom);

But I need get the tile z/x/y numbers. ST_SquareGrid actually returns a record with a geometry, i, and j. These i and j are the position in the grid and can be converted to x and y. This math, and a bit of SQL to handle multipolygons vs. polygons lets me get a list of z/x/y

WITH nonmatch AS (

SELECT ST_SymDifference(ST_Collect(old.way), ST_Collect(new.way)) AS dgeom

FROM (select x, y, way from water_polygons) old

FULL OUTER JOIN (select x, y, way from loading.water_polygons) new

ON old.way = new.way and old.x = new.x and old.y = new.y

WHERE new.way IS NULL OR old.way IS NULL

GROUP BY COALESCE(old.x, new.x), COALESCE(old.y, new.y)),

differences AS (SELECT (ST_Dump(dgeom)).geom AS geom FROM nonmatch)

SELECT DISTINCT

z,

LEAST(GREATEST(0, squares.i+2^(z-1)), 2^z - 1) AS x,

LEAST(GREATEST(0, squares.j*-1+2^(z-1)), 2^z - 1) AS y

FROM differences,

generate_series(10,14) AS z,

ST_SquareGrid(40075016.685578/2^z, differences.geom) AS squares

WHERE ST_Intersects(differences.geom, squares.geom);

Running this on coastline data few days apart gives about 1000 tiles that need re-rendering.

For the OSMF Shortbread vector tiles I had to identify when coastlines has changed. The solution I came up isn’t specific to Shortbread, but is useful for anyone using the tiled ocean shapefiles.

I’m going to start by assuming that the old ocean data is in

water_polygons and the new data is in loading.water_polygons. Other parts of my code already handle this. The shapefiles are loaded into tables that have the columns x int, y int, way geometry.To start I want to find any geometries that have changed. For geometries in the new data that aren’t in the old data, I can get this with a

LEFT JOIN. I want a set of geometries that includes any geometries from the new data that aren’t in the old. This set can be made by excluding any geometries in the old data that have identical x, y, and binary identical geometry to a new geometry. It’s possible this set includes extra geometries, but that’s okay.A

RIGHT JOIN would find geometries in the old data that aren’t in the new. Combining these gives a FULL OUTER JOIN. If I then collect the geometries in each shapefile tile I can compare them to find the geometriesSELECT ST_SymDifference(ST_Collect(old.way), ST_Collect(new.way)) AS dgeom

FROM water_polygons AS old

FULL OUTER JOIN loading.water_polygons AS new

ON old.way = new.way and old.x = new.x and old.y = new.y

WHERE new.way IS NULL OR old.way IS NULL

GROUP BY COALESCE(old.x, new.x), COALESCE(old.y, new.y)

This gets me the difference in geometries for the entire world in about two minutes. But I need tiles, which is it’s own complication.

I need to intersect the changes with potential tial geometries. This could be done by generating lots of tiles with ST_TileEnvelope, but there’s a better function. ST_SquareGrid generates the square grid that covers a geometry’s bounding box. If I use the right settings, these correspond to standard tiles. I can then exclude any that don’t intersect the geometry.

This can be done with

SELECT

...

FROM differences,

generate_series(10,14) AS z,

ST_SquareGrid(40075016.685578/2^z, differences.geom) AS squares

WHERE ST_Intersects(differences.geom, squares.geom);

But I need get the tile z/x/y numbers. ST_SquareGrid actually returns a record with a geometry, i, and j. These i and j are the position in the grid and can be converted to x and y. This math, and a bit of SQL to handle multipolygons vs. polygons lets me get a list of z/x/y

WITH nonmatch AS (

SELECT ST_SymDifference(ST_Collect(old.way), ST_Collect(new.way)) AS dgeom

FROM (select x, y, way from water_polygons) old

FULL OUTER JOIN (select x, y, way from loading.water_polygons) new

ON old.way = new.way and old.x = new.x and old.y = new.y

WHERE new.way IS NULL OR old.way IS NULL

GROUP BY COALESCE(old.x, new.x), COALESCE(old.y, new.y)),

differences AS (SELECT (ST_Dump(dgeom)).geom AS geom FROM nonmatch)

SELECT DISTINCT

z,

LEAST(GREATEST(0, squares.i+2^(z-1)), 2^z - 1) AS x,

LEAST(GREATEST(0, squares.j*-1+2^(z-1)), 2^z - 1) AS y

FROM differences,

generate_series(10,14) AS z,

ST_SquareGrid(40075016.685578/2^z, differences.geom) AS squares

WHERE ST_Intersects(differences.geom, squares.geom);

Running this on coastline data few days apart gives about 1000 tiles that need re-rendering.

Now, let’s talk about English.

Why is English so widespread today?

Why is it such a dominant and influential language?

Is it because it’s superior?

Absolutely not. It is because English is the language of empire.

I bear no grudge against the English language itself—but I do feel profound sorrow and regret over this historical reality.

Had a different Asian country colonized yours, perhaps you would now be speaking that language instead of English—or perhaps a language even less prominent globally.

Please understand this: English is not dominant because it is better, easier to learn, or inherently more suited to communication.

Have you ever imagined a foreigner—someone who speaks a different language—breaking into a cold sweat as they struggle to understand the language and follow the flow of conversation, all while feeling overwhelmed by unfamiliar social behaviors and caught in a situation where loud, rapid chatter goes on, and on, and on, without a moment to catch up or make sense of what’s going on?

Some of you say, “No one is stopping you from speaking your native language.”

Some of you say, “Don’t just stay in your local community—come out and join the global conversation.”

But only those who are confident in their English, or those like me who cannot bear the frustration of silence, make the effort to break through the language barrier and speak here.

Would you say to that person, “No one’s stopping you—try to jump in,” or “It’s okay, just speak in your native language”?

Wouldn’t that, in fact, feel even more humiliating than simply walking away?

Why is English so widespread today?

Why is it such a dominant and influential language?

Is it because it’s superior?

Absolutely not. It is because English is the language of empire.

I bear no grudge against the English language itself—but I do feel profound sorrow and regret over this historical reality.

Had a different Asian country colonized yours, perhaps you would now be speaking that language instead of English—or perhaps a language even less prominent globally.

Please understand this: English is not dominant because it is better, easier to learn, or inherently more suited to communication.

Have you ever imagined a foreigner—someone who speaks a different language—breaking into a cold sweat as they struggle to understand the language and follow the flow of conversation, all while feeling overwhelmed by unfamiliar social behaviors and caught in a situation where loud, rapid chatter goes on, and on, and on, without a moment to catch up or make sense of what’s going on?

Some of you say, “No one is stopping you from speaking your native language.”

Some of you say, “Don’t just stay in your local community—come out and join the global conversation.”

But only those who are confident in their English, or those like me who cannot bear the frustration of silence, make the effort to break through the language barrier and speak here.

Would you say to that person, “No one’s stopping you—try to jump in,” or “It’s okay, just speak in your native language”?

Wouldn’t that, in fact, feel even more humiliating than simply walking away?

Western-centric worldview...

Now, let’s talk about English. Why is English so widespread today? Why is it such a dominant and influential language? Is it because it’s superior? Absolutely not. It is because English is the language of empire.OpenStreetMap

One person is sanding down a rusty gate,

Another is painting over the rust,

Yet another is attaching a new handle to the corroded gate,

Some are even building an entirely new gate to replace the old, rusted one

And a few are wondering, Why are they d…

Another is painting over the rust,

Yet another is attaching a new handle to the corroded gate,

Some are even building an entirely new gate to replace the old, rusted one

And a few are wondering, Why are they d…

The world of OSM, where everyone just does their own thing without coordination or adjustment.

It sometimes feels like OSM is of the West, by the West, for the West.

Over the past 20 years, OpenStreetMap has become one of the worlds largest and most impactful crowdsourcing projects.

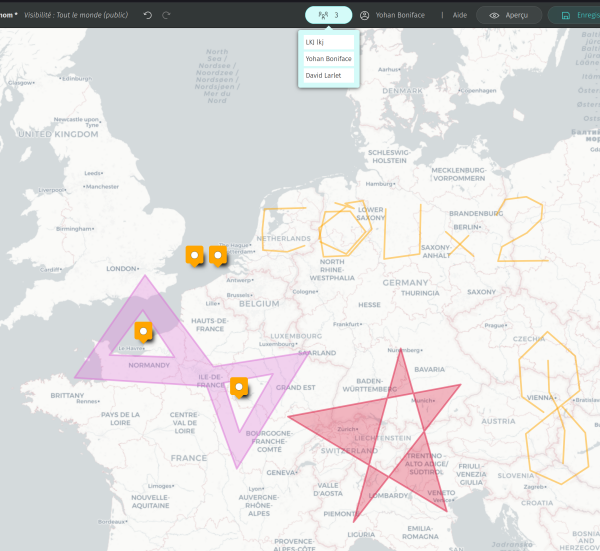

After one more year of French administration funding (thank you!), we are so proud to have released versions 3.X of uMap since last April. Since then, we made a couple of adjustments to ease the deployment of that new version.

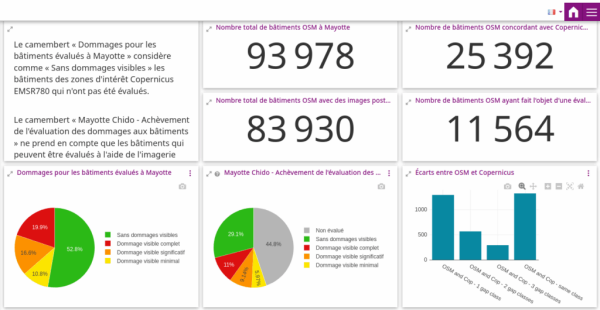

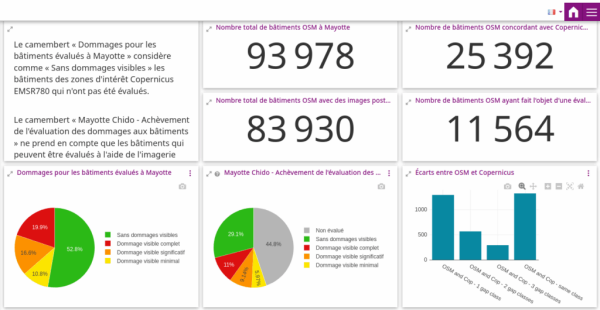

Cartographie OSM des dommages du bâti à Mayotte après Chido - nouveaux indicateurs et premiers résultats

Cartographie OSM des dommages du bâti à Mayotte après Chido - nouveaux indicateurs et premiers résultats

Cet article de blog a été publié à lorigine sur ce site web et a déjà été mentionné par WeeklyOSM.OpenStreetMap

Magnetic Yokes Machine Magnetic Particle Testing (MPT) is one of the most widely used non-destructive testing (NDT) methods for the detection of surface and near-surface flaws in ferromagnetic materials. The Magnetic Yoke Machine is considered one of the more popular tools used for MPT due to its portability, ease of operation, and efficacy. What is a Magnetic Yoke Machine? A Magnetic Yoke is a handheld or portable device that generates a magnetic field using either AC (Alternating Current) or DC (Direct Current). It consists of a U-shaped or C-shaped core with adjustable legs and an electromagnetic coil. Generally, once energized, it induces a magnetic field into the test piece, allowing the inspectors to check for cracks, seams, and other defects using magnetic particles. Types of Magnetic Yokes AC Yokes: Best for detecting surface cracks due to shallow penetration. DC Yokes: These offer deeper penetration and allow for identification of subsurface flaws. Permanent Magnetic Yokes: These employ strong magnets instead of electricity and are suited for hazardous environments. Electromagnetic Yokes: These require power (battery or mains) and offer adjustable strength. Advantages of Magnetic Yokes Portable and lightweight: Suitable for carrying anywhere for site inspection. Fast Setup: No additional preparations are needed. Versatile: Suitable for flat, curved, or irregular surfaces. Cost-effective: In contrast to more sophisticated NDT equipment, it is an inexpensive option. How to Use a Magnetic Yoke? Clean All Surfaces – To do this, you need to remove rust, paint, and dirt. Apply Magnetic Particles – You spray dry or wet particles. Place the Yoke – Put the legs over the area to be inspected. Magnetize and Inspect – Turn on the yoke and look for accumulation of particles at defects. Demagnetizer – Preventing residual magnetism. Conclusion The Magnetic Yoke Machine is portable, easy to use and economic test equipment for detecting surface cracks on ferromagnetic materials. It is best suited for inspection in welding, aerospace and manufacturing, ensuring quicker and more confident defect detection thereafter.

Magnetic Yoke Machine

Magnetic Yokes Machine Magnetic Particle Testing (MPT) is one of the most widely used non-destructive testing (NDT) methods for the detection of surface and near-surface flaws in ferromagnetic materials.OpenStreetMap